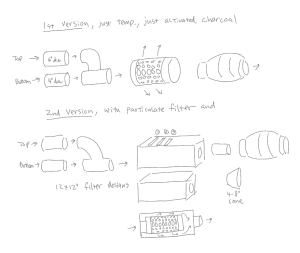

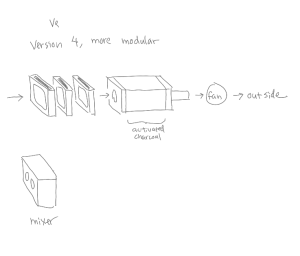

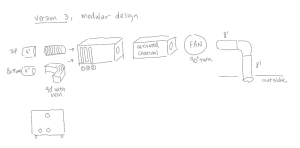

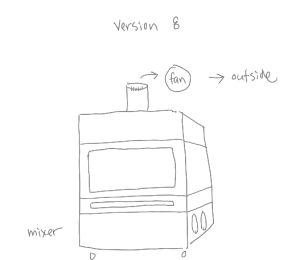

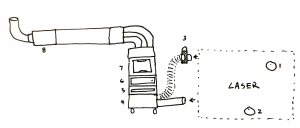

DIY Laser Fume Extractor: Pre-Version 8.2 Units

Previous Laser Fume Extractor Versions:

Before we reached the current working version of Bernie, 8.2, the DIY Laser Fume Extractor, there were many mistakes and many revisions to the designs and prototypes. Here are some for your entertainment:

\

\